Sintered NdFeB hlau nplaumyog cov hlau nplaum hlau ua los ntawm Nd, Fe, B thiab lwm yam hlau. Nws yog dav siv nyob rau hauv mini-motors, cua generators, meters, sensors, hais lus, sib nqus ncua kev kawm ntawv system, sib nqus kis tshuab thiab lwm yam kev siv. Ib qho yooj yim heev rau corrosion nyob rau hauv qhov chaw ntub dej, yog li nws yog qhov tsim nyog los ua qhov kev kho saum npoo raws li cov neeg siv khoom xav tau. Peb tuaj yeem muab cov txheej txheem, xws li Zinc, Nickel, Nickel-copper-nickel, Nyiaj, kub-plating, Epoxy txheej, thiab lwm yam Qib: N35-N52, N35M-48M, N33H-N44H, N30SH-N42SH, N28UH-N38UH, N28EH-

Txheej txheem ntawm Sintered Neodymium Magnet Manufacturing

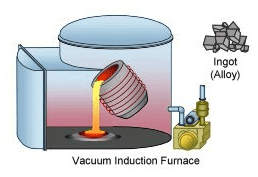

Cov khoom siv hlau nplaum thiab lwm yam hlau raug cuam tshuam rau nruab nrab zaus thiab yaj hauv qhov cub induction.

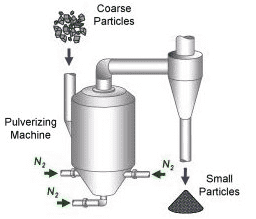

Tom qab ua tiav ntawm ntau yam txheej txheem, cov ingots yog pulverized rau hauv cov khoom uas muaj ob peb microns loj. Txhawm rau tiv thaiv oxidation los ntawm qhov tshwm sim, cov khoom me me raug tiv thaiv los ntawm nitrogen.

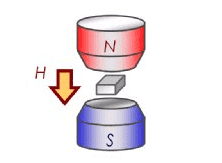

Cov khoom sib nqus tau muab tso rau hauv ib lub jig thiab ib qho chaw sib nqus yog siv thaum cov hlau nplaum raug nias rau hauv cov duab feem ntau. Tom qab pib shaping, roj isostatic nias yuav mus ntxiv rau daim duab.

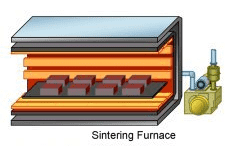

Cov khoom sib nqus tau muab tso rau hauv ingots uas tau nias thiab yuav tsum tau kho cua sov hauv qhov cub sintering. Qhov ceev ntawm cov ingots ua ntej tsuas yog hits 50% ntawm qhov tseeb ntom rau sintering. Tab sis tom qab sineing, qhov tseeb ceev yog 100%. Los ntawm cov txheej txheem no, kev ntsuas ntawm ingots yuav luag 70% -80% thiab nws qhov ntim yog txo los ntawm 50%.

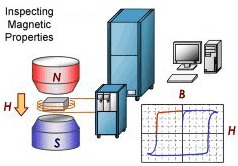

Cov khoom sib nqus yooj yim tau teeb tsa tom qab sintering thiab aging txheej txheem tiav. Cov kev ntsuas tseem ceeb suav nrog cov seem flux ntom ntom, coercive, thiab cov khoom siv hluav taws xob siab tshaj plaws raug kaw.

Tsuas yog cov hlau nplaum uas dhau qhov kev soj ntsuam raug xa mus rau cov txheej txheem tom ntej, xws li machining thiab assembling.

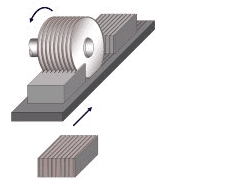

Vim yog shrinkage los ntawm cov txheej txheem sintering, yuav tsum tau ntsuas yog tiav los ntawm kev sib tsoo cov hlau nplaum nrog abrasives. Pob zeb diamond abrasives yog siv rau cov txheej txheem no vim tias cov hlau nplaum nyuaj heev.

Txhawm rau kom zoo tshaj plaws rau ib puag ncig uas lawv yuav siv, cov hlau nplaum raug rau ntau yamkev kho saum npoo. Nd-Fe-B hlau nplaum feem ntau raug rau xeb nrog zoo li NiCuNi hlau nplaum, Zn, Epoxy, Sn, Dub Nickel.

Tom qab plating, ntsig txog kev ntsuas thiab kev tshuaj xyuas qhov muag yuav ua kom paub meej tias peb cov khoom siv hlau nplaum zoo li. Dhau li ntawd, txhawm rau xyuas kom meej qhov siab, peb kuj yuav tsum tau kuaj qhov ntau thiab tsawg los tswj qhov kam rau ua.

Thaum cov tsos thiab qhov ntau thiab tsawg kam rau siab ntawm cov hlau nplaum tsim nyog, nws yog lub sij hawm los ua magnetization magnetic kev taw qhia.

Tom qab kuaj xyuas thiab sib nqus, cov hlau nplaum tau npaj ntim nrog lub thawv ntawv, txawm tias ntoo pallet raws li cov neeg siv khoom xav tau. Sib nqus Flux tuaj yeem raug cais los ntawm cov hlau rau huab cua lossis nthuav qhia lub sijhawm.

Post lub sij hawm: Jan-25-2021